Oakley Grove School

Carrick Construction completed the build of the external sports surfaces including two natural turf...

Carrick was principal contractor on this project and a key requirement was to be mindful of the operations of Lambeth Council (LC) and other contractors while delivering the works. Carrick was in control of the site throughout but had to adhere to the requirements of LC.

On this project both LC and Woodmansterne School (WS) were engaged throughout development of the Construction Phase Plan (CPP) to ensure any routine activities such as planned preventative maintenance, were notified to Carrick with relevant RAMS and Safe Systems of Work (SSoW) reviewed and signed off.

Project milestones were clear in the CPP and project GANTT with regular meetings with all engaged stakeholders to assess progress, assessment of any potential showstoppers and continual review of performance. Throughout this project Carrick had to implement, maintain and manage shared site access routes for the client and Carrick operatives. Set down areas for materials, site compounds, welfare and security fences were established.

Carrick provided the client with weekly reporting, and other stakeholders such as the school and governors, in order to assess the progress of the work throughout.

The weekly report consisted of progress information, actual utilisation of manpower, construction equipment and the status of tests and inspections.

Indicative minimum chapter breakdown included contract information, health and safety, programme and progress, quality management, weather, commercial/budget, design, requests for information, site team and progress photos.

Site management included a dedicated site agent, possessing SMSTS as minimum. Site inductions, daily briefings and site noticeboards gave information on walking and vehicular routes around site, ensuring the segregation of plant and persons. The CCP factored in this information and was updated to include any changes.

Daily works briefings attended by trade/operative supervisors were completed to discuss the following days work, this information was the basis for daily briefings and ensured there were no clashes in the schedules of the disciplines across the site. Through the project, Carrick ensured the COM area was secure and only qualified persons entered the site. Due to the presence of sealants, fuels and other chemicals, COSHH assessments were carried out and MSDS stored in the site file and factored into the development of RAMS and SSoW. Bunded fuel storage areas were set up and COSHH storage cabinets were available, locked and suitably labelled.

Site mobilisation was factored into the CPP and was reviewed and approved by the client and other stakeholders. Welfare facilities were provided and these were kept clean at all times. Solar power was used to run the welfare, with generator back up. Effluent was removed from site by tanker. All non-construction waste was placed in skips provided. Waste materials were placed in segregated skips, for re-use or recycling wherever possible. All products that couldn’t be recycled were removed from site to a licensed tip facility. Waste transfer notes were supplied by the haulage company providing proof all waste was disposed of responsibly. STRI factor the carbon footprint and embedded carbon in products used. In particular, on this project, Carrick used exocellular products that were made from recycled polymers. All aggregates were sourced from local quarries.

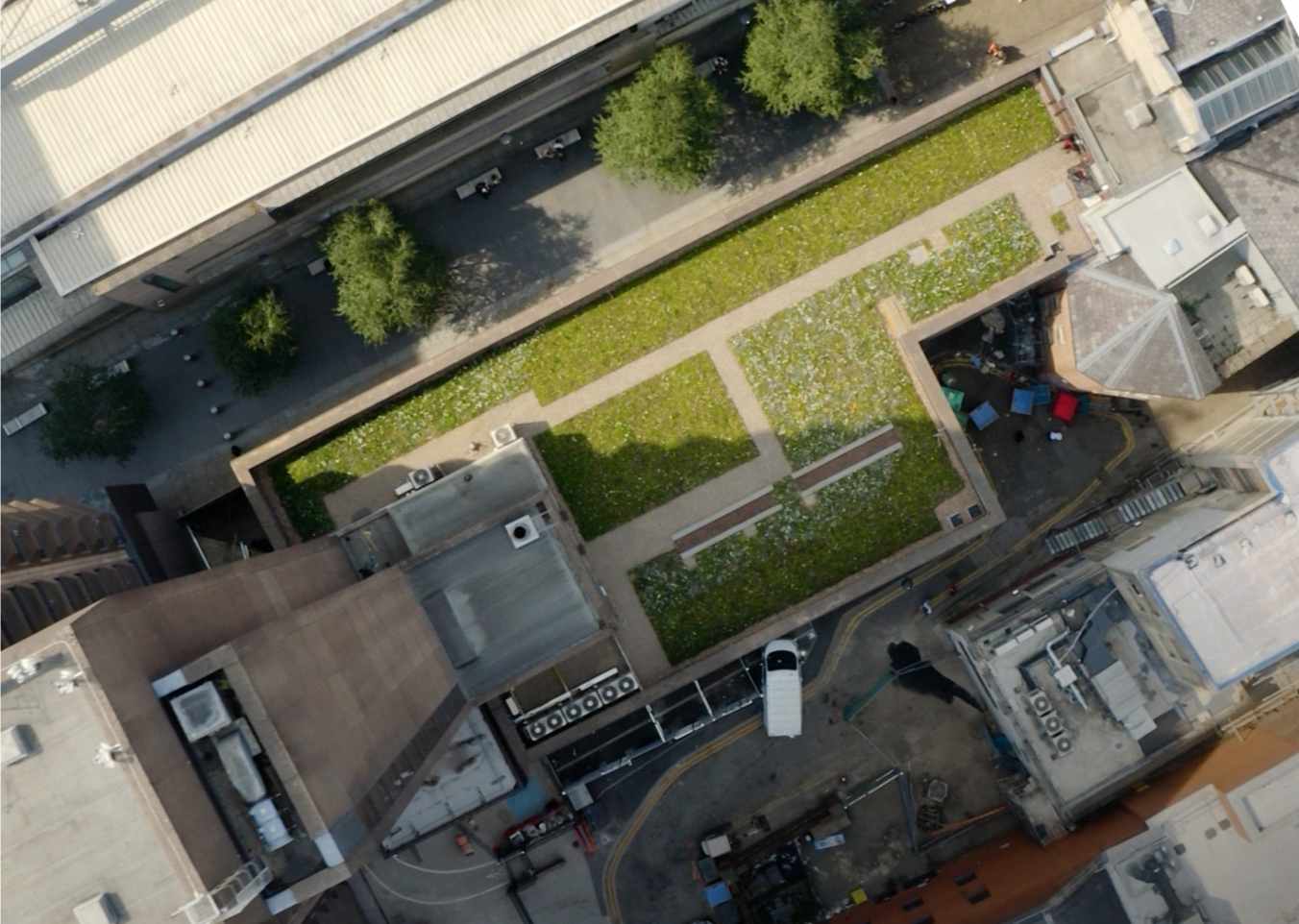

Due to the inner-city location of the site, Carrick was faced with the consequent lack of storage facilities meaning there was a need to deviate from normal procedures. The project faced high temperatures throughout the build which meant adjustments to the timescales.

This meant that rather than a standard delivery of materials and machinery, this was staggered over a number of days, using early morning deliveries. Also, the movement of the materials and machinery from kerbside to rooftop was undertaken safely and as quickly as possible to cause minimal disruption to the local neighbourhood. The collaborative design and construction team worked closely to safely work through the challenges as they arose such as ensuring that the maximum weight capacity of the roof was not exceeded at set points.

To combat the high temperatures, the bespoke wildflower turf had to be laid rapidly and heavily irrigated to prevent irreversible damage. The initial construction schedule of three weeks was achieved in just two weeks through a combination of long days and careful planning.

Read more about our expertise in sports pitch construction, design, drainage and water management or get in touch today to discuss your requirements.